Business Process

Full-Process Professional

Efficient Service

Pre-Sales Discussion

Comprehensive And In-Depth

Planning And Design

Excellent Delivery

Worry-Free After-Sales Service

Customer Benefits

The Industrial Manufacturer

That Knows You Best

That Knows You Best

Increased Production Efficiency And Improved Product Quality

Intelligent Decision-Making And Lean Management

Customized Personalization And Flexible Manufacturing

Optimization Of Human And Material Resources

Digitalization

Information Digitalization Operations

Intelligentization

Intelligent Production Productivity Increased by 3% to 12%

Innovative Model

Lean Management Efficiency Increased by ≥50%

Energy Saving And Environmental Protection

Electricity Consumption Saved by 5% to 20%, Paper Waste Reduced by 55%

Exception Improvement

Failure Rate Reduced by 5% to 17%, Processing Rate Increased by 20% to 40%

Example Showcase

IIOT (Industrial Internet Of Things) Equipment Intelligent Maintenance System

The IIOT (Industrial Internet Of Things) Equipment Intelligent Maintenance System is an intelligent maintenance system developed for customers, designed to meet their needs for improvement in four major areas: management, personnel, equipment, and materials. It achieves digitalization of records, materials, and energy, as well as intelligent management, scheduling, and production, thereby enhancing the overall benefits for the customers.

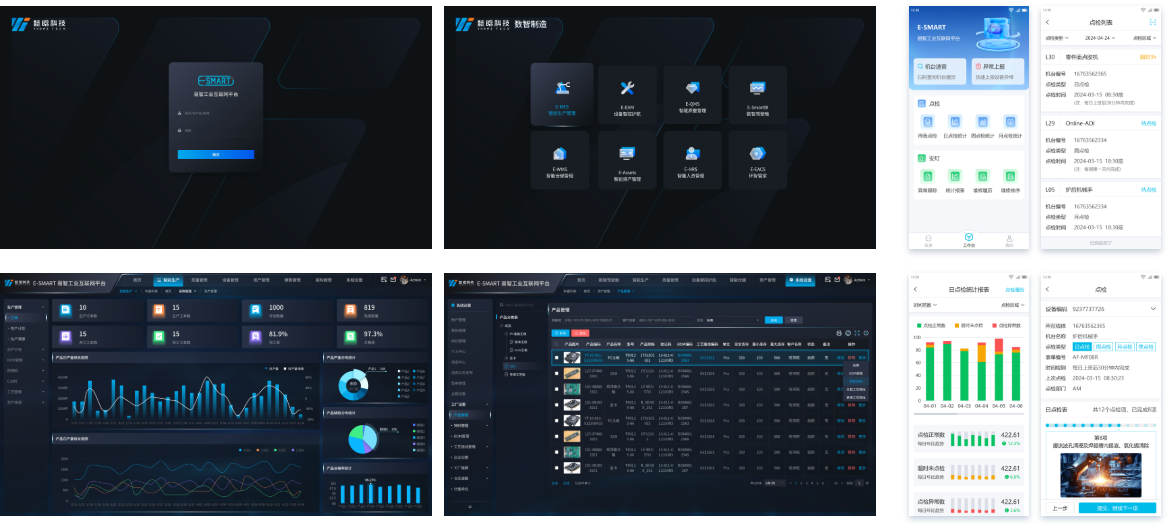

The E-SMART Industrial Internet Platform

The E-SMART Industrial Internet Platform includes eight major modules: Command Center, Intelligent Production, Intelligent Monitoring, Intelligent Human Resources, Intelligent Maintenance, Intelligent Plant Area, Intelligent Quality, and Intelligent Storage. These modules help enterprises achieve digital transformation and intelligent upgrading in various aspects of production and management.

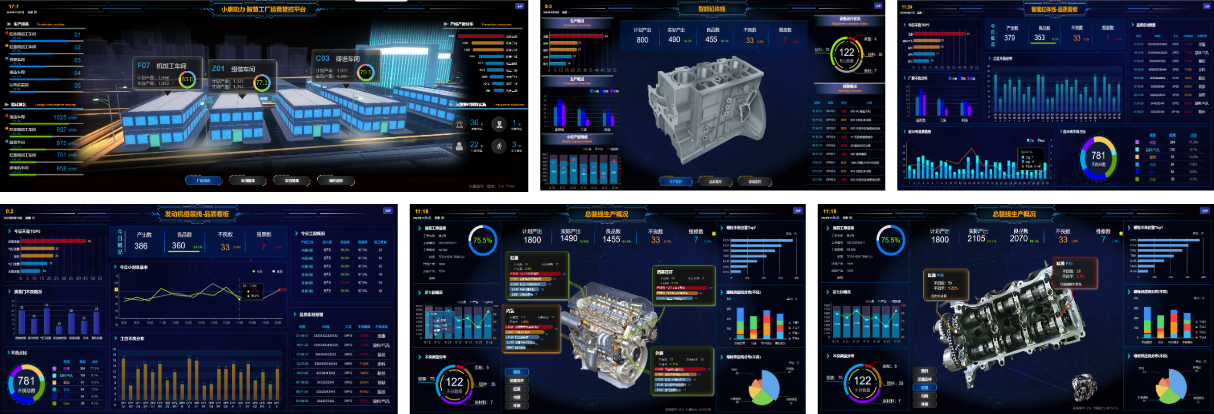

Auto Power BU Manufacturing System

Auto Power BU Manufacturing System realizes intelligent production for customers from multiple aspects such as Production management, Quality Management, Equipment Maintenance, iTrace ect. Through real-time collection and analysis of equipment data, it connects the full chain information of equipment, personnel, production, management, etc., helping enterprises achieve the construction of a digital intelligent manufacturing platform.

Lean Machining System

The Lean Machining System is specifically designed for machining production. It utilizes intelligent sensing and data analysis, along with real-time monitoring, to automatically intervene in the machining process when common tool failures such as tool breakage, chipping, adhesion, swarf entanglement, and wear occur and exceed set boundaries. Interventions include alerts, alarms, and machine shutdowns to prevent further damage to subsequent tools, batch scrap / rework, and machine tool damage, It makes the machining process visualizable.

3C Automatic Assembly Equipment

The system use an IPC to control the overall motion system, and CCD for product QR code, visual inspection, and visual alignment. Mainly used for high-precision visual automatic mounting of accessories on 3C products (mobile phones / tablets / laptops), it has functions such as scanning, mounting, dispensing, film tearing, and re inspection (optional), and can achieve material compatibility assembly.

PCB Intelligent Tool Library Management System

The PCB Intelligent Tool Library Management System is based on the PCB tool intelligent sorting machine. By integrating the intelligent tool library management system with visual recognition and mechanical sorting, it can achieve rapid sorting and tool allocation. This not only saves labor but also improves work efficiency and realizes the transformation to digital and intelligent operations.

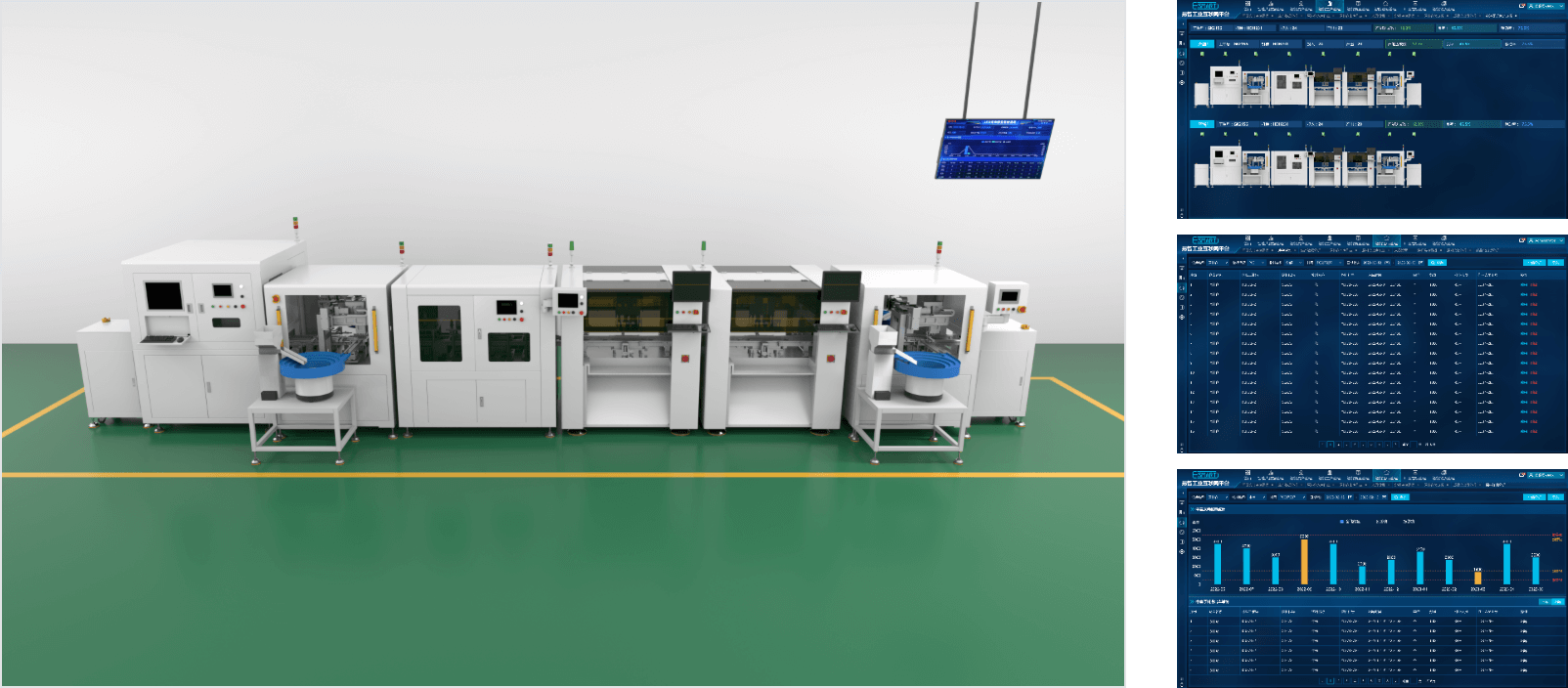

LED Chip Intelligent Production Line

The LED Chip Intelligent Production Line enhances production efficiency through the design and optimization of machinery. Combined with a production statistics monitoring system and real-time dashboards at the line head, it monitors production capacity and quality, optimizing management and workshop production control.

Cooperative Customers